IPLUSMOBOT's AMR intelligent logistics solution deeply empowers flexible panel manufacturing, running through the front, middle, and back core processes and the whole process logistics in the factory. It accurately meets the industry's extremely high requirements for the cleanliness of the production environment, millimeter-level accuracy of material handling, and system flexibility, and successfully realizes the full process of automated, intelligent, and traceable flexible logistics from raw materials to finished products, effectively improving production efficiency, product yield, and digital management level of the factory.

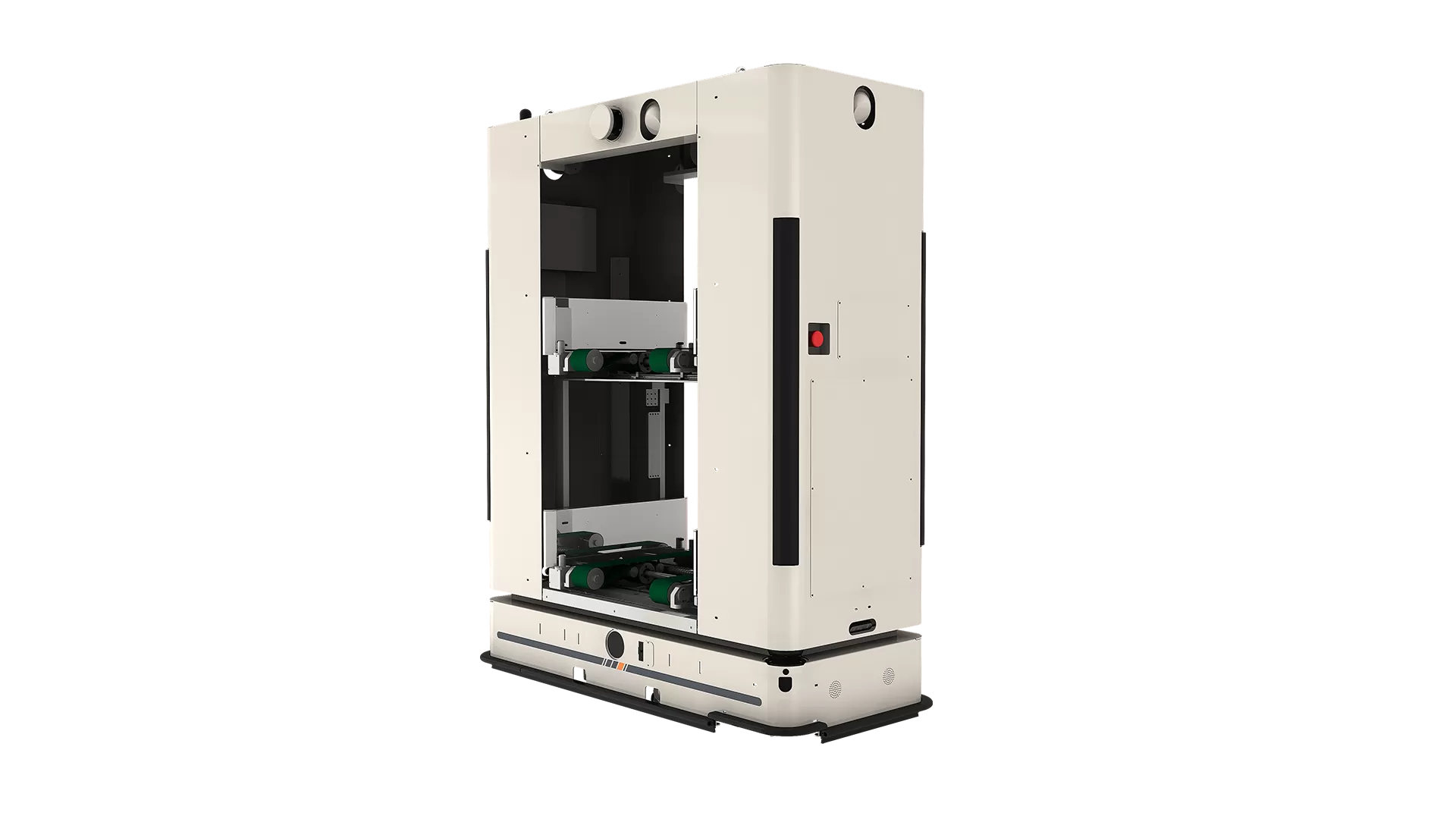

Exclusive chassis structure design, which can meet the needs of different levels of clean room space applications

Millimeter-level operation accuracy, combined with anti-vibration design and advanced control algorithms, ensures safe and reliable material handling

Efficient task allocation, path planning, and traffic control ensure continuous and stable operation 24/7

Accurate tracking and data binding of the whole process to meet the requirements of quality control and product traceability