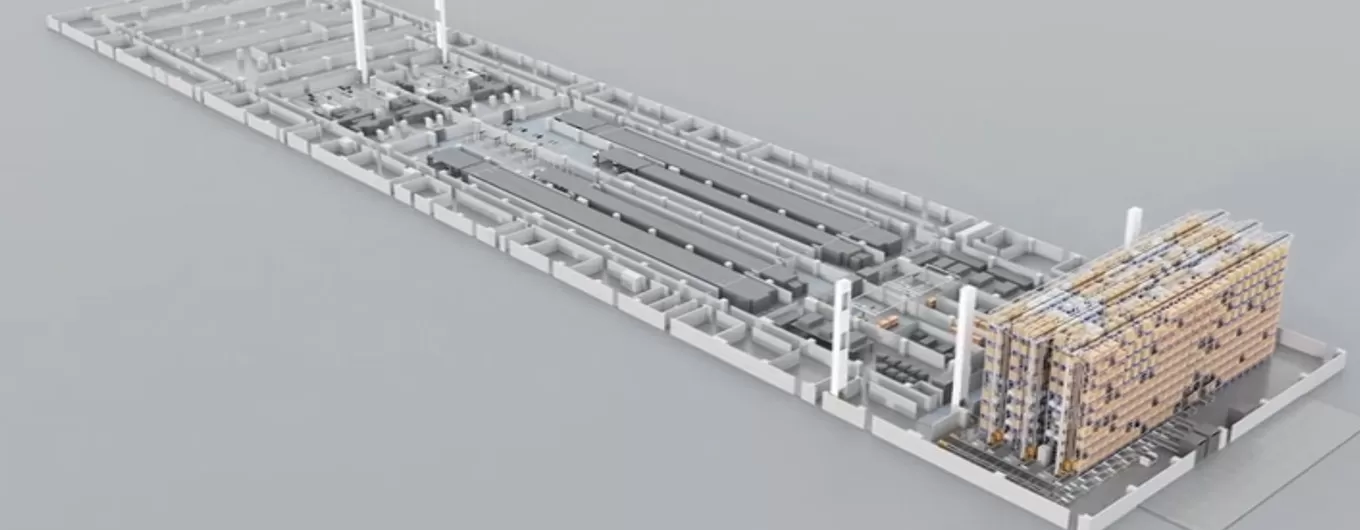

With the rapid development of the lithium battery industry, IPLUSMOBOT offers an integrated flexible solution covering the entire manufacturing process from electrode and cell manufacturing, module assembly, to PACK packaging. Utilizing laser SLAM and vision fusion navigation, our robots achieve millimeter-level precision docking, enabling automated docking and handling of auxiliary materials, electrode rolls, and battery cells. Seamless integration with the factory MES enables fully digital and intelligent production.

Operates 24/7, enhancing production efficiency, and lowering personnel management costs.

Accurately handlings materials such as winding rolls and battery cells along preset paths, ensuring smooth production flow.

Seamlessly connects all processes from raw material storage to coating and cutting, forming a closed-loop logistics system.

Real-time monitoring of material location and status provides data support for production decisions and optimization.