We go beyond automation with an intelligently integrated ecosystem:

CLOUDIA’s predictive cloud platform analyzes demand patterns and optimizes resource allocation across facilities;

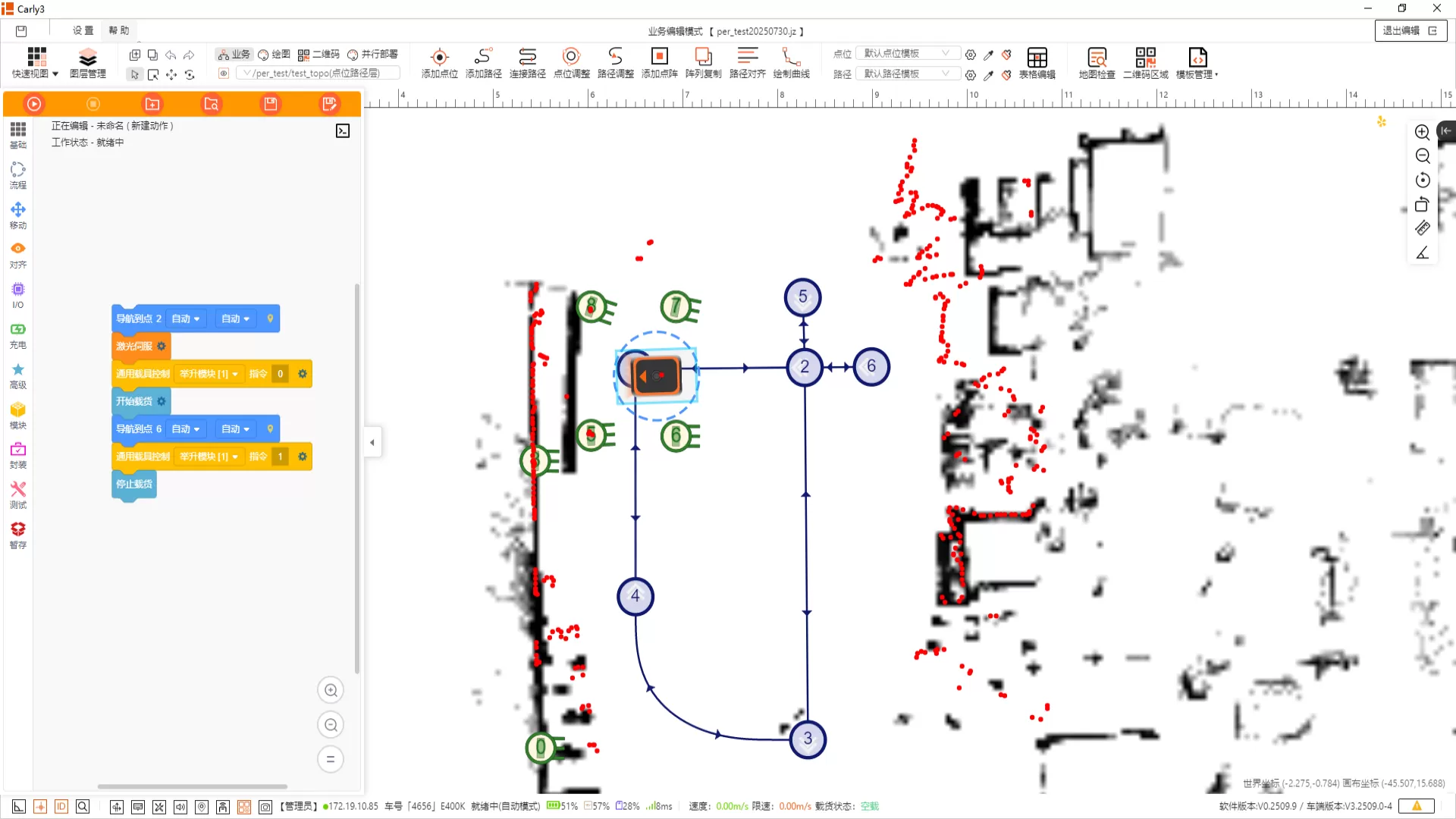

CARLY’s real-time fleet orchestrator coordinates AMR swarms with military-grade collision avoidance and traffic control;

and OWL’s AI-driven warehouse OS synchronizes inventory management with workflow automation—all connected via a unified data fabric.

This integrated system enables self-optimizing operations that reduce energy costs by 28% through intelligent load balancing, achieve 99.9% fleet uptime with prescriptive maintenance, and triple picking density using adaptive slotting.

By combining predictive intelligence, real-time execution, and business process integration, we deliver 25–40% lower total cost of ownership and seamless scalability to handle 100% peak-season demand, transforming static warehouses into adaptive logistics systems that evolve through machine learning.

100+ AMR instant scheduling & multi-device control.

Al dynamic path planning +self-learning algorithms.

Modular architecture, 72-hour launch.

Seamless APl integration with MES/ERP/WCS.

3D visual monitoring with real-time analytics.

OTA remote updates for evergreen intelligence.